Product Description

Product Description

| Details of the figure | Detailed sizes | |||||

| Size | A | B | C | D | E | |

| mm | mm | mm | mm | mm | mm | |

| M15 | 12 | 13 | 61 | 15 | 6 | |

| M20 | 13.5 | 17.5 | 72 | 20 | 7 | |

| M25 | 15 | 20 | 83 | 25 | 11 | |

| M32 | 15 | 19.5 | 88 | 30 | 12 | |

| M50 | 19 | 23 | 117.5 | 48.5 | 13 | |

| Details of the figure | Detailed sizes | |||||

| Size | A | B | C | D | E | |

| mm | mm | mm | mm | mm | mm | |

| M15 | 12.5 | 13 | 61 | 15 | 5.5 | |

| M20 | 14 | 18 | 73 | 20 | 6.5 | |

| M25 | 16 | 20 | 85 | 25 | 10 | |

| M32 | 15.5 | 20 | 92.5 | 30 | 10 | |

| M50 | 19 | 31 | 132.5 | 50 | 13 | |

| Details of the figure | Detailed sizes | |||||

| Size | A | B | C | D | E | |

| mm | mm | mm | mm | mm | mm | |

| M75 | 23 | 33 | 155 | 75 | 15 | |

| M100 | 25 | 40 | 191 | 100 | 17 | |

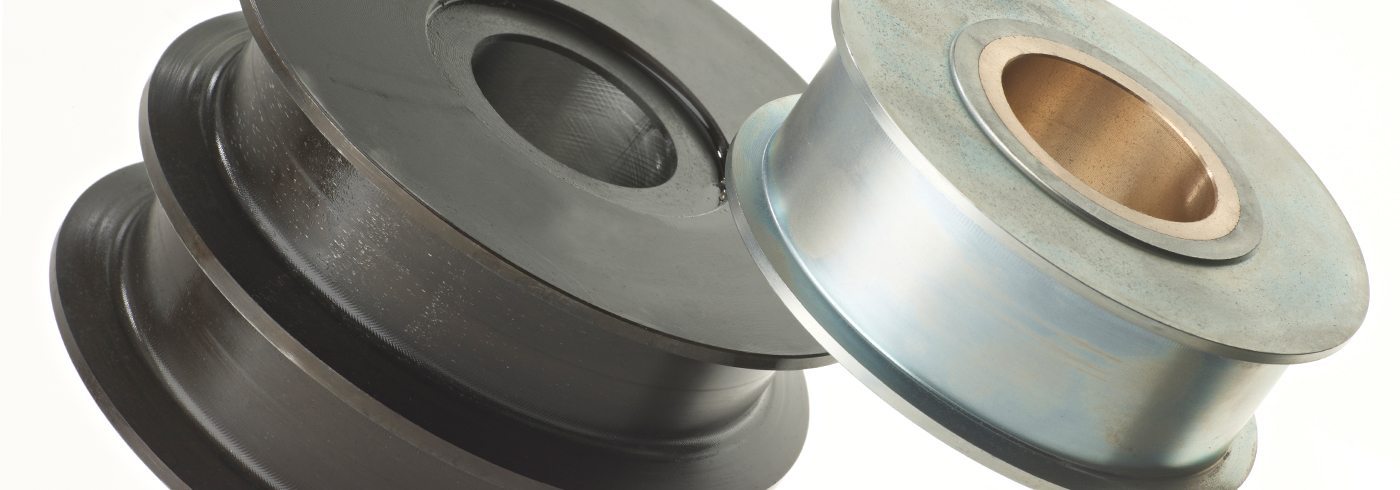

Detailed Photos

Certifications

Company Profile

ZheJiang CHINAMFG Metal Products Co., Ltd. offers a variety of products which can meet your multifarious demands.

We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Surface: | Bright Smooth |

|---|---|

| Material: | Stainless Steel 304 |

| Size: | 15mm-100mm |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do chain pulleys enhance the precision and control of lifting operations?

Chain pulleys play a significant role in enhancing the precision and control of lifting operations. Here are some ways in which chain pulleys contribute to precise and controlled lifting:

1. Mechanical Advantage:

Chain pulleys utilize a system of sheaves and chains, which creates a mechanical advantage. This allows operators to exert less force while lifting heavy loads. The mechanical advantage provided by chain pulleys enables smoother and more controlled lifting motions, reducing the risk of sudden movements that can compromise precision.

2. Multiple Sheaves:

Chain pulleys often feature multiple sheaves or wheels that guide the chain and distribute the load. By using multiple sheaves, the load can be evenly distributed, minimizing the possibility of imbalance or tilting during the lifting process. This promotes stability and control.

3. Variable Speed Options:

Some chain pulley systems offer variable speed options, allowing operators to adjust the lifting speed according to the specific requirements of the task. This feature enhances control by enabling operators to lift and position loads at a desired pace, ensuring accurate and precise placement.

4. Load Positioning:

Chain pulleys provide the ability to vertically lift loads and position them with accuracy. The pulley system allows for controlled vertical movement, enabling operators to raise or lower loads to precise heights. This is particularly useful in applications where precise positioning is necessary, such as assembly lines or construction sites.

5. Control Mechanisms:

Chain pulleys can incorporate control mechanisms to further enhance precision and control. These mechanisms may include braking systems or clutches that allow operators to stop or control the speed of lifting operations with greater accuracy. Such control mechanisms enable operators to perform delicate maneuvers and adjust the lifting process as needed.

6. Fine Adjustments:

Chain pulleys provide the capability for fine adjustments during lifting operations. By using the appropriate control mechanisms or manual adjustments, operators can make precise changes in the lifting height or position of the load. This level of fine-tuning ensures that the load is precisely placed or aligned, meeting the required specifications.

7. Operator Input:

Chain pulleys rely on manual operation, which allows the operator to have direct control over the lifting process. Operators can closely monitor the load, respond to any unexpected changes, and make real-time adjustments to maintain precision and control throughout the operation.

Overall, chain pulleys enhance precision and control in lifting operations through their mechanical advantage, multiple sheaves, variable speed options, load positioning capabilities, control mechanisms, fine adjustments, and operator input. These features make chain pulleys versatile tools for achieving accurate and controlled lifting in various industries and applications.

Are there different types of chain pulleys, and how do they vary in applications?

Yes, there are different types of chain pulleys, each designed for specific applications based on various factors such as load capacity, speed, environment, and the type of chain used. Here's an overview of some common types of chain pulleys and their varying applications:

1. Roller Chain Pulleys:

- Roller chain pulleys are widely used in industrial applications that require high-load carrying capacity and durability. They consist of toothed wheels with grooves designed to accommodate the chain's rollers.

- These pulleys are commonly used in conveyor systems, power transmission systems, and heavy machinery, where they provide reliable and efficient power transfer.

2. Silent Chain Pulleys:

- Silent chain pulleys, also known as inverted tooth chain pulleys, are used in applications that require high-speed and smooth operation with minimal noise.

- They are commonly found in automotive engines, motorcycles, and other machinery that require precise timing and synchronization between rotating components.

3. Double Pitch Chain Pulleys:

- Double pitch chain pulleys are designed for applications that require low-speed and light-load operation, such as in conveyor systems for small products or lightweight materials.

- They feature a larger pitch than standard roller chain pulleys, resulting in reduced chain weight and cost.

4. Conveyor Chain Pulleys:

- Conveyor chain pulleys are specialized pulleys used in conveyor systems for material handling applications.

- These pulleys are designed with specific features to ensure proper engagement and smooth movement of the conveyor chain, facilitating efficient material transportation in industries such as mining, agriculture, and manufacturing.

5. Timing Chain Pulleys:

- Timing chain pulleys are utilized in applications that require precise timing and synchronization between rotating components, such as in internal combustion engines.

- These pulleys are commonly found in automotive engines, where they ensure accurate valve and camshaft timing for optimal engine performance.

6. Leaf Chain Pulleys:

- Leaf chain pulleys are used in applications requiring high-strength and high-load capacity, such as lifting devices and hoists.

- These pulleys are designed to accommodate leaf chains, which consist of interlocking links and provide excellent resistance to fatigue and wear.

7. Hollow Pin Chain Pulleys:

- Hollow pin chain pulleys are used in applications where the chain needs to pass through the pulley, such as in overhead conveyors or equipment with limited space.

- These pulleys feature a hollow pin design that allows the chain to pass through the pulley, facilitating easy installation and maintenance.

When selecting a chain pulley for a specific application, it is essential to consider factors such as load capacity, speed requirements, chain type compatibility, environmental conditions, and the specific demands of the machinery or system.

By choosing the appropriate type of chain pulley, one can ensure optimal performance, longevity, and efficiency in various industrial and mechanical applications.

What are the advantages of using chain pulleys in various lifting tasks?

Chain pulleys, also known as chain blocks or chain hoists, offer several advantages in a wide range of lifting tasks. Here are some of the key advantages of using chain pulleys:

1. High Lifting Capacity:

Chain pulleys are capable of lifting heavy loads with ease. They are designed to handle various weight capacities, allowing for efficient lifting of materials and equipment that may be too heavy to lift manually.

2. Mechanical Advantage:

A chain pulley provides mechanical advantage through its pulley system. By utilizing multiple pulleys, it amplifies the force applied, enabling operators to lift heavy loads with less effort. This mechanical advantage reduces the strain on the operator and improves productivity.

3. Precise and Controlled Lifting:

Chain pulleys offer precise and controlled lifting operations. The operator can regulate the lifting speed and adjust the position of the load with ease, ensuring accurate placement and minimizing the risk of damage to the load or surrounding structures.

4. Versatility:

Chain pulleys are versatile tools suitable for various lifting tasks. They can be used in different orientations, such as vertical lifting, horizontal pulling, or angled pulling. This adaptability allows for flexibility in handling different types of loads and accommodating diverse work environments.

5. Portability and Ease of Use:

Chain pulleys are designed to be portable and easy to use. They are typically lightweight and compact, making them convenient for transportation and installation in different locations. Additionally, they are user-friendly, requiring minimal training for operation.

6. Safety Features:

Chain pulleys are equipped with safety features to ensure secure lifting operations. These may include load limiters to prevent overloading, safety hooks with latches to securely attach the load, and brake systems to control the movement and prevent accidental lowering of the load. These safety features contribute to the protection of both the operator and the lifted load.

7. Durability:

Chain pulleys are built to withstand demanding work environments. They are constructed with sturdy materials, such as alloy steel or stainless steel, which provide excellent durability and resistance to wear and corrosion. This durability ensures a long service life, even in rugged conditions.

8. Cost-Effective Solution:

Chain pulleys offer a cost-effective solution for lifting tasks. They are relatively affordable compared to other lifting equipment, while still providing reliable and efficient performance. Additionally, their low maintenance requirements contribute to cost savings over time.

9. Wide Range of Applications:

Chain pulleys find application in various industries and settings, including construction, manufacturing, warehouses, shipbuilding, mining, and entertainment. Their versatility and lifting capabilities make them suitable for a diverse range of lifting tasks in different sectors.

These advantages highlight why chain pulleys are favored for lifting tasks. They provide efficient, safe, and flexible solutions, improving productivity and reducing manual effort in various lifting operations.

editor by CX

2024-05-16