Product Description

Product Description

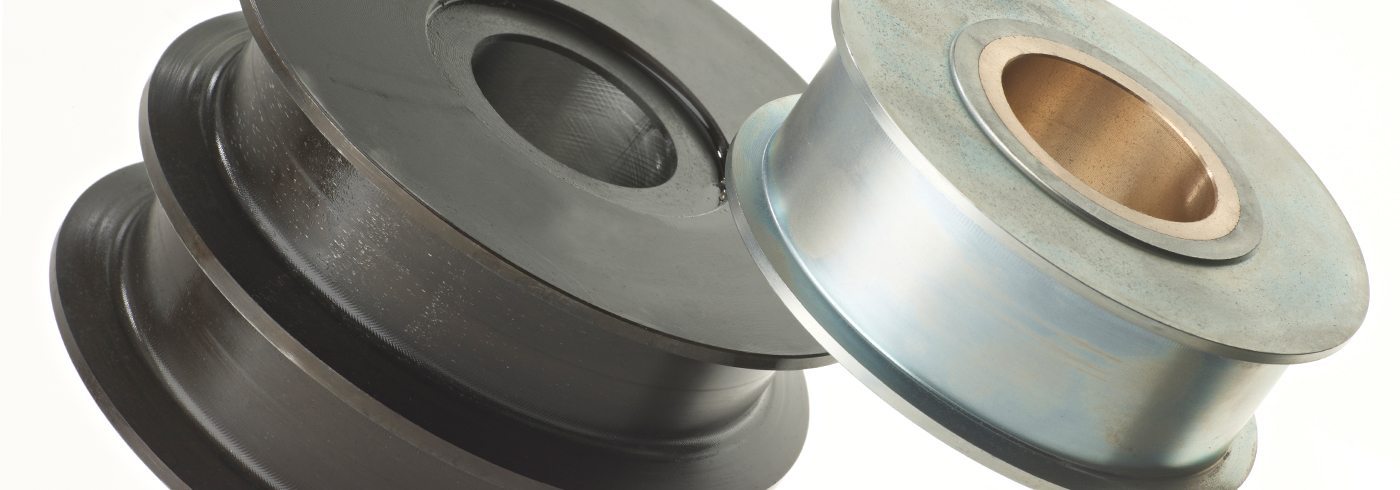

Heavy Duty Single Sheave Snatch Lifting Block Chain Link Pulley

Heavy Duty Single Sheave Snatch Lifting Block Pulley is Widely Used in American, Asian as well as the Mid East. It is 1 kind of most popular Cable Pulley Block all over the world. The size is from 3"-18". NOTE *Special marks can be made according to customers' requirments. *Special package can be made according to customers' requirements. *We also offer steel wire rope, wire rope thimble, wire rope sleeve, high quality Chains, connecting link, eye ling hook, eye self locking hook, master link, master link assembly, welded master link, welded master link assembly, CHINAMFG link, etc.

Product Parameters

Heavy Duty Single Sheave Snatch Lifting Block Chain Link Pulley

| SIZE | CODE | S.W.L. | DIAM OF ROPE | QTY/CASE | N.W/G.W | WD SIZE |

| inch | ton | mm | pcs | kg | cm | |

| 5 | HYR12-6601 | 3 | 18~20 | 40 | 268/290 | 110x61x48 |

| 6 | HYR12-6602 | 5 | 20~22 | 40 | 464/474 | 114x66x54 |

Certifications

Packaging & Shipping

Payment Term

Exhibition

Our Factory

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Manufacturing Process: | Casting |

| Material: | Carbon Steel |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you select the right chain pulley configuration for a specific lifting task?

Selecting the right chain pulley configuration is essential to ensure safe and efficient lifting operations. Here are the key factors to consider when choosing the appropriate chain pulley for a specific lifting task:

1. Load Capacity:

Determine the maximum weight of the load that needs to be lifted. Choose a chain pulley with a load capacity that exceeds the weight of the load to ensure it can handle the required lifting capacity without straining the system.

2. Working Environment:

Consider the environmental conditions in which the chain pulley will be used. Factors such as temperature, humidity, corrosive substances, and exposure to dirt or dust can impact the performance and longevity of the pulley. Select a chain pulley that is suitable for the specific working environment to ensure optimal durability and reliability.

3. Lifting Height and Distance:

Determine the height to which the load needs to be lifted and the horizontal distance it needs to be moved. This information will help determine the required length of the chain and the number of sheaves needed in the pulley system to achieve the desired lifting height and reach.

4. Speed and Control:

Consider the desired lifting speed and level of control required for the lifting task. Depending on the application, you may need a chain pulley system with features that allow for precise load positioning and control. Additionally, consider whether a single-speed or multi-speed pulley system is needed to accommodate the specific lifting requirements.

5. Safety Considerations:

Ensure that the selected chain pulley configuration includes safety features such as load limiters, safety hooks with latches or swivels, and mechanisms to prevent overloading. These safety features are essential for safeguarding both the operators and the lifting operation.

6. Maintenance and Serviceability:

Consider the maintenance requirements and ease of serviceability of the chain pulley. Opt for a configuration that allows for convenient lubrication, inspection, and maintenance to ensure the longevity and optimal performance of the pulley system.

7. Compliance with Regulations:

Ensure that the selected chain pulley configuration complies with relevant industry standards and regulations. Adhering to safety standards and regulations is crucial to ensure the safe and legal operation of the lifting equipment.

By carefully considering these factors, you can select the right chain pulley configuration that aligns with the specific lifting task requirements, ensuring safe and efficient lifting operations.

How do chain pulleys contribute to the safe and efficient lifting of loads?

Chain pulleys play a crucial role in enabling safe and efficient lifting of loads in various applications. Here's how they contribute to achieving these objectives:

1. Mechanical Advantage:

Chain pulley systems provide a mechanical advantage that allows users to lift heavy loads with reduced effort. By utilizing multiple sheaves and chains, the applied force is distributed across the system, making it easier to lift heavier objects compared to direct manual lifting.

2. Load Control:

Chain pulleys offer precise and controlled load handling. Operators can easily regulate the movement and position of the load by manipulating the chain. This level of control is particularly important in delicate or complex lifting operations where accuracy and precision are required.

3. Versatility:

Chain pulleys are versatile tools that can be used in various lifting applications. They are suitable for both light and heavy loads, making them adaptable to different industries and scenarios. Chain pulleys can be found in construction sites, warehouses, manufacturing facilities, and many other environments where lifting is required.

4. Increased Safety:

Chain pulleys incorporate safety features that enhance the safe lifting of loads. These features may include load limiters, safety hooks with latches or swivels, and mechanisms to prevent overloading. Additionally, chain pulleys provide stability and minimize the risk of load slippage or sudden drops, ensuring the safety of both the operators and the surrounding environment.

5. Durability and Reliability:

Chain pulleys are designed to withstand heavy loads and frequent use. They are typically constructed with robust materials such as alloy steel or stainless steel, ensuring durability and longevity. When properly maintained and lubricated, chain pulleys can provide consistent and reliable performance over extended periods.

6. Efficiency and Productivity:

Using chain pulleys can significantly improve lifting efficiency and productivity. The mechanical advantage they offer allows for faster and more efficient lifting compared to manual methods. This can save time and labor, increasing overall productivity in lifting operations.

7. Cost-Effectiveness:

Chain pulleys provide a cost-effective solution for lifting heavy loads. They are generally more affordable than alternative lifting mechanisms, such as hydraulic or pneumatic systems. Additionally, their durability and low maintenance requirements contribute to long-term cost savings.

Overall, chain pulleys are essential tools that contribute to the safe and efficient lifting of loads. They provide mechanical advantage, precise load control, versatility, increased safety, durability, reliability, efficiency, and cost-effectiveness. With their wide range of benefits, chain pulleys are widely used in various industries to streamline lifting operations and ensure the well-being of operators and the integrity of the lifted loads.

In which industries and settings are chain pulleys commonly employed?

Chain pulleys, also known as chain blocks or chain hoists, find widespread use in various industries and settings due to their versatility and lifting capabilities. Here are some industries and settings where chain pulleys are commonly employed:

1. Construction Industry:

Chain pulleys are extensively used in the construction industry for lifting and hoisting heavy materials and equipment. They are commonly employed in construction sites for tasks such as lifting steel beams, concrete blocks, scaffolding, and precast components.

2. Manufacturing and Industrial Facilities:

Manufacturing and industrial facilities utilize chain pulleys for a wide range of lifting applications. They are used for lifting and moving heavy machinery, equipment, and components during installation, maintenance, and production processes. Chain pulleys are particularly valuable in manufacturing industries such as automotive, aerospace, and heavy machinery.

3. Warehouses and Distribution Centers:

In warehouses and distribution centers, chain pulleys are used for efficient handling and storage of heavy goods. They are employed for lifting and moving pallets, crates, and containers, making the loading and unloading of trucks and shelves more manageable.

4. Shipbuilding and Maritime Industry:

Chain pulleys play a crucial role in the shipbuilding and maritime industry. They are used for lifting heavy ship components, such as engines, anchors, and propellers, during construction, repair, and maintenance operations. Chain pulleys are also employed in ports and harbors for cargo handling and ship loading/unloading.

5. Mining and Extraction:

In the mining and extraction industry, chain pulleys are utilized for lifting and moving heavy materials and machinery. They are commonly employed in mines and quarries for tasks such as lifting rocks, ores, and mining equipment.

6. Power Plants and Utilities:

Chain pulleys are employed in power plants and utility settings for various lifting applications. They are used for lifting heavy transformers, generators, and other equipment during installation, maintenance, and repair operations.

7. Entertainment and Event Industry:

In the entertainment and event industry, chain pulleys are employed for rigging and lifting purposes. They are used for suspending lighting and sound equipment, stage props, and scenery during concerts, theater productions, and other events.

8. Workshops and Garages:

Chain pulleys find application in workshops and garages for tasks such as engine lifting, vehicle maintenance, and repairs. They provide a reliable and efficient solution for lifting heavy automotive components.

9. Agriculture and Farming:

In the agricultural and farming sector, chain pulleys are used for lifting and moving heavy loads, such as bales of hay, animal feed, and farm equipment.

These are just a few examples of the industries and settings where chain pulleys are commonly employed. Their versatility, strength, and ease of use make them valuable lifting tools in various sectors.

editor by CX

2024-05-16