Product Description

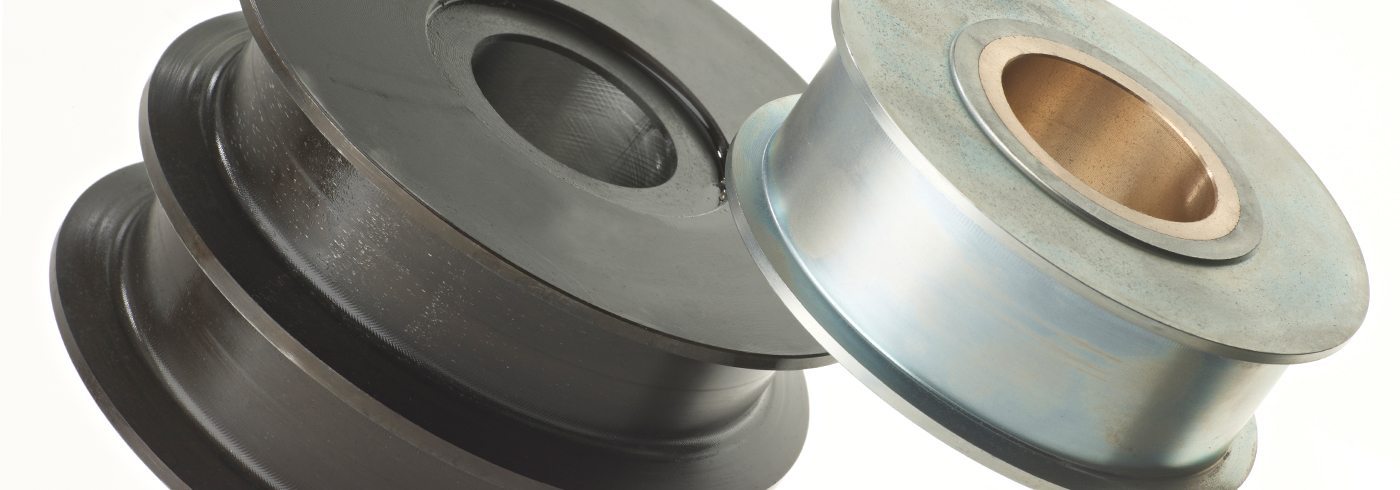

China Supplier Chain Tensioner Assembly OEM16620-0W571 Belt Tensioner Pulley

PRODUCT SPERCIFICATION

|

Item Name.: |

Belt Tensioner Pulley |

Car Make: |

Highlander |

| OEM: | 16620-0W571 |

Quality |

100% tested |

| SIZE | Standard |

OEM Order |

Welcomed |

|

MOQ |

10PCS |

Certification |

ISO9001/ TS16949 |

|

Place of Origin |

China |

Warranty |

1 years |

|

Color |

same as picture |

Payment |

Alipay,paypal, T/T, W/U, MoneyGram |

|

Packing |

Neutral /fengming/original/Customized |

Delivery time |

3-10days |

If you are interest in our products,please feel free to contact me

What we can promise you?

1. Manufacturing & Selling Integration

2. Our companies located in HangZhou China which are in charge of different markets

3. 1 Year warranty for Fengming brand products under normal use

4. Unique Fengming brand packing: one Fengming poly bag plus one Fengming red box

5. Competitive price with high & stable quality products

6. Total 2,000 square meters warehouse to make sure fast delivery

7. 10 years' experience in researching, developing and supplying auto parts for Japanese cars since 2009

Customer Reviews:

95% positive testmonials from customers around the world. Fengming brand products' quality, packing and Fengming service get excellent approval among customers. Seeing is believing!

Fengming Auto Parts CO., Ltd main products line:

Auto ignition system: Spark Plug, Ignition Coil

Suspension Parts: shock absorber, control arm, ball joint,stabilizer link, tie rod end, steering rack

Brake parts: brake pads, brake disc, brake master cylinder, wheel cylinder

Fuel pump, water pump, radiator, full gasket kit, engine belt

HangZhou Fengming Auto Parts CO., Ltd company profile:

HangZhou Fengming AUTO PARTS CO., LTD specializes in manufacturing and selling engine parts for Japanese cars, established in 2009. Fengming AUTO PARTS has developed more than 4000 different kinds of products for Japanese applications like Toyota, Honda, Nissan, Mitsubishi, Mazda and including brake pads,ignition coil, oxygen sensor, water pump, power steering rack, timing belt kit etc. We have been committed to providing high efficiency, quality guaranteed, long durability auto parts to our customers. Until now Fengming Auto Parts CO., Ltd has cooperated with many big factories such as Aisin,DENSO,KYB in order to meet customers' needs in different countries. Now we have more than 200 workers with the production capacity of 50,000 to 100,000 sets every month. And we have built up warehouses total covering area 2,000 square meters in HangZhou China, thus, we are able to deliver goods to you promptly.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Samples: |

US$ 13.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations should be kept in mind when working with chain pulleys?

Working with chain pulleys requires strict adherence to safety guidelines to prevent accidents and ensure the well-being of operators and bystanders. Here are some important safety considerations to keep in mind:

1. Proper Training and Competence:

Only trained and competent personnel should operate chain pulleys. Operators should have a thorough understanding of the equipment, its limitations, and safe operating procedures. Regular training and refresher courses should be provided to ensure operators are up-to-date with safety protocols.

2. Equipment Inspection and Maintenance:

Inspect the chain pulley and associated components before each use to identify any signs of wear, damage, or malfunction. Ensure proper lubrication of moving parts and promptly address any maintenance or repair needs. Faulty or damaged equipment should not be used and should be taken out of service for repair or replacement.

3. Weight Limitations and Load Capacity:

Never exceed the weight limit or load capacity specified by the manufacturer for the chain pulley. Overloading can lead to equipment failure, causing accidents and injuries. It is crucial to accurately determine the weight of the load and select the appropriate chain pulley with the necessary load capacity.

4. Secure Attachment and Rigging:

Ensure that the chain pulley is securely attached to a stable and suitable anchor point. Proper rigging techniques should be employed to secure the load and prevent slippage or detachment during lifting operations. Use appropriate hooks, shackles, or other rigging devices that are rated for the load and compatible with the chain pulley.

5. Personal Protective Equipment (PPE):

Operators should wear appropriate personal protective equipment, such as safety helmets, gloves, and eye protection, when working with chain pulleys. PPE helps protect against potential hazards, including falling objects, hand injuries, and eye injuries.

6. Clear Communication and Signaling:

Establish clear communication protocols between the operator and other personnel involved in the lifting operation. Use standardized signals or communication devices to ensure everyone understands the commands and actions to be taken during the lifting process.

7. Avoiding Sudden Load Release:

Never release the load suddenly or allow it to freefall. Lower the load in a controlled manner, ensuring that there are no personnel or obstacles in the path of the descending load. Sudden load release can cause accidents and injuries.

8. Environmental Considerations:

Take into account the working environment and any specific hazards it may present. For example, working in extreme temperatures, high winds, or confined spaces may require additional safety measures or precautions to be taken.

9. Emergency Preparedness:

Have a plan in place for responding to emergencies or equipment failures during lifting operations. Train personnel on emergency procedures and ensure the availability of appropriate rescue and first-aid equipment.

10. Regulatory Compliance:

Adhere to applicable safety regulations, standards, and codes when working with chain pulleys. Familiarize yourself with the specific requirements of your industry and location to ensure compliance with legal obligations.

By following these safety considerations and promoting a safety-conscious work environment, the risks associated with working with chain pulleys can be minimized, and accidents can be prevented.

Are there different types of chain pulleys, and how do they vary in applications?

Yes, there are different types of chain pulleys, each designed for specific applications based on various factors such as load capacity, speed, environment, and the type of chain used. Here's an overview of some common types of chain pulleys and their varying applications:

1. Roller Chain Pulleys:

- Roller chain pulleys are widely used in industrial applications that require high-load carrying capacity and durability. They consist of toothed wheels with grooves designed to accommodate the chain's rollers.

- These pulleys are commonly used in conveyor systems, power transmission systems, and heavy machinery, where they provide reliable and efficient power transfer.

2. Silent Chain Pulleys:

- Silent chain pulleys, also known as inverted tooth chain pulleys, are used in applications that require high-speed and smooth operation with minimal noise.

- They are commonly found in automotive engines, motorcycles, and other machinery that require precise timing and synchronization between rotating components.

3. Double Pitch Chain Pulleys:

- Double pitch chain pulleys are designed for applications that require low-speed and light-load operation, such as in conveyor systems for small products or lightweight materials.

- They feature a larger pitch than standard roller chain pulleys, resulting in reduced chain weight and cost.

4. Conveyor Chain Pulleys:

- Conveyor chain pulleys are specialized pulleys used in conveyor systems for material handling applications.

- These pulleys are designed with specific features to ensure proper engagement and smooth movement of the conveyor chain, facilitating efficient material transportation in industries such as mining, agriculture, and manufacturing.

5. Timing Chain Pulleys:

- Timing chain pulleys are utilized in applications that require precise timing and synchronization between rotating components, such as in internal combustion engines.

- These pulleys are commonly found in automotive engines, where they ensure accurate valve and camshaft timing for optimal engine performance.

6. Leaf Chain Pulleys:

- Leaf chain pulleys are used in applications requiring high-strength and high-load capacity, such as lifting devices and hoists.

- These pulleys are designed to accommodate leaf chains, which consist of interlocking links and provide excellent resistance to fatigue and wear.

7. Hollow Pin Chain Pulleys:

- Hollow pin chain pulleys are used in applications where the chain needs to pass through the pulley, such as in overhead conveyors or equipment with limited space.

- These pulleys feature a hollow pin design that allows the chain to pass through the pulley, facilitating easy installation and maintenance.

When selecting a chain pulley for a specific application, it is essential to consider factors such as load capacity, speed requirements, chain type compatibility, environmental conditions, and the specific demands of the machinery or system.

By choosing the appropriate type of chain pulley, one can ensure optimal performance, longevity, and efficiency in various industrial and mechanical applications.

In which industries and settings are chain pulleys commonly employed?

Chain pulleys, also known as chain blocks or chain hoists, find widespread use in various industries and settings due to their versatility and lifting capabilities. Here are some industries and settings where chain pulleys are commonly employed:

1. Construction Industry:

Chain pulleys are extensively used in the construction industry for lifting and hoisting heavy materials and equipment. They are commonly employed in construction sites for tasks such as lifting steel beams, concrete blocks, scaffolding, and precast components.

2. Manufacturing and Industrial Facilities:

Manufacturing and industrial facilities utilize chain pulleys for a wide range of lifting applications. They are used for lifting and moving heavy machinery, equipment, and components during installation, maintenance, and production processes. Chain pulleys are particularly valuable in manufacturing industries such as automotive, aerospace, and heavy machinery.

3. Warehouses and Distribution Centers:

In warehouses and distribution centers, chain pulleys are used for efficient handling and storage of heavy goods. They are employed for lifting and moving pallets, crates, and containers, making the loading and unloading of trucks and shelves more manageable.

4. Shipbuilding and Maritime Industry:

Chain pulleys play a crucial role in the shipbuilding and maritime industry. They are used for lifting heavy ship components, such as engines, anchors, and propellers, during construction, repair, and maintenance operations. Chain pulleys are also employed in ports and harbors for cargo handling and ship loading/unloading.

5. Mining and Extraction:

In the mining and extraction industry, chain pulleys are utilized for lifting and moving heavy materials and machinery. They are commonly employed in mines and quarries for tasks such as lifting rocks, ores, and mining equipment.

6. Power Plants and Utilities:

Chain pulleys are employed in power plants and utility settings for various lifting applications. They are used for lifting heavy transformers, generators, and other equipment during installation, maintenance, and repair operations.

7. Entertainment and Event Industry:

In the entertainment and event industry, chain pulleys are employed for rigging and lifting purposes. They are used for suspending lighting and sound equipment, stage props, and scenery during concerts, theater productions, and other events.

8. Workshops and Garages:

Chain pulleys find application in workshops and garages for tasks such as engine lifting, vehicle maintenance, and repairs. They provide a reliable and efficient solution for lifting heavy automotive components.

9. Agriculture and Farming:

In the agricultural and farming sector, chain pulleys are used for lifting and moving heavy loads, such as bales of hay, animal feed, and farm equipment.

These are just a few examples of the industries and settings where chain pulleys are commonly employed. Their versatility, strength, and ease of use make them valuable lifting tools in various sectors.

editor by CX

2024-05-15