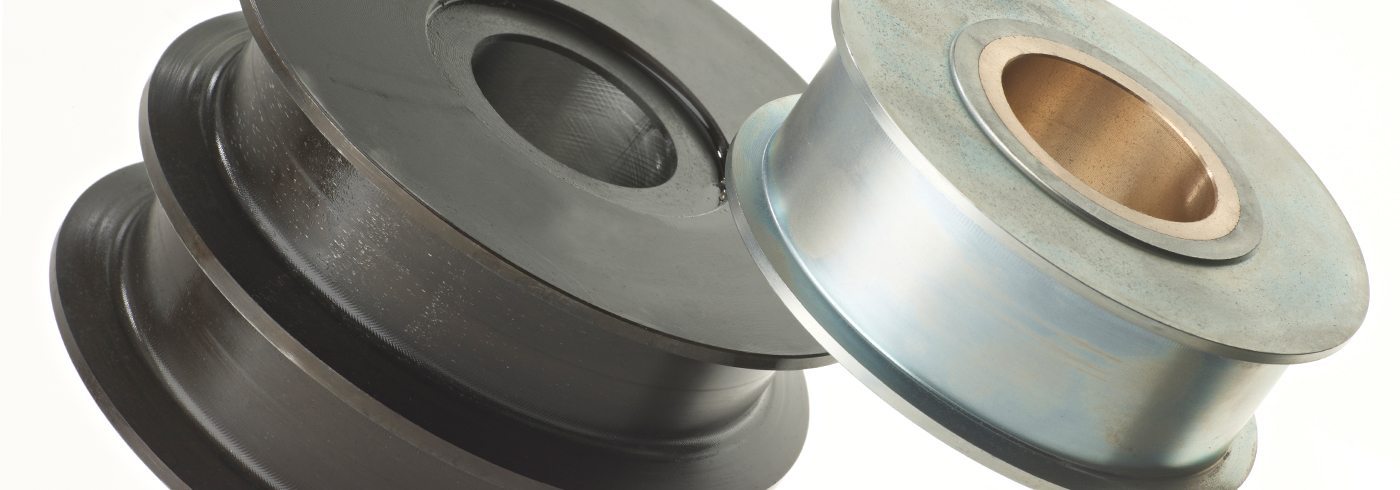

Product Description

|

CHINAMFG Industry ltd specializes in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system.

With keeping manufacturing process design, quality plHangZhou, key manufacturing processes and final quality control in house we are mastering key competence to supply quality mechanical parts and assembly to our customers for both China and Export Market .

To satisfy different mechanical and functional requirements from our customers we are able to make a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are able to provide professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Casting Method: | Investment Casting, Option Lost Wax Casting |

|---|---|

| Casting Form Material: | G25crmo4, G35, Wcb |

| Casting Metal: | Cast Steel |

| Casting Form Usage Count: | Permanent |

| Surface Treatment: | Dacromat Coating, Finish Painting |

| Surface Roughness: | 0.005mm-0.01mm-0.1mm |

| Samples: |

US$ 0.89/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do chain pulleys enhance the precision and control of lifting operations?

Chain pulleys play a significant role in enhancing the precision and control of lifting operations. Here are some ways in which chain pulleys contribute to precise and controlled lifting:

1. Mechanical Advantage:

Chain pulleys utilize a system of sheaves and chains, which creates a mechanical advantage. This allows operators to exert less force while lifting heavy loads. The mechanical advantage provided by chain pulleys enables smoother and more controlled lifting motions, reducing the risk of sudden movements that can compromise precision.

2. Multiple Sheaves:

Chain pulleys often feature multiple sheaves or wheels that guide the chain and distribute the load. By using multiple sheaves, the load can be evenly distributed, minimizing the possibility of imbalance or tilting during the lifting process. This promotes stability and control.

3. Variable Speed Options:

Some chain pulley systems offer variable speed options, allowing operators to adjust the lifting speed according to the specific requirements of the task. This feature enhances control by enabling operators to lift and position loads at a desired pace, ensuring accurate and precise placement.

4. Load Positioning:

Chain pulleys provide the ability to vertically lift loads and position them with accuracy. The pulley system allows for controlled vertical movement, enabling operators to raise or lower loads to precise heights. This is particularly useful in applications where precise positioning is necessary, such as assembly lines or construction sites.

5. Control Mechanisms:

Chain pulleys can incorporate control mechanisms to further enhance precision and control. These mechanisms may include braking systems or clutches that allow operators to stop or control the speed of lifting operations with greater accuracy. Such control mechanisms enable operators to perform delicate maneuvers and adjust the lifting process as needed.

6. Fine Adjustments:

Chain pulleys provide the capability for fine adjustments during lifting operations. By using the appropriate control mechanisms or manual adjustments, operators can make precise changes in the lifting height or position of the load. This level of fine-tuning ensures that the load is precisely placed or aligned, meeting the required specifications.

7. Operator Input:

Chain pulleys rely on manual operation, which allows the operator to have direct control over the lifting process. Operators can closely monitor the load, respond to any unexpected changes, and make real-time adjustments to maintain precision and control throughout the operation.

Overall, chain pulleys enhance precision and control in lifting operations through their mechanical advantage, multiple sheaves, variable speed options, load positioning capabilities, control mechanisms, fine adjustments, and operator input. These features make chain pulleys versatile tools for achieving accurate and controlled lifting in various industries and applications.

How are chain pulleys customized for specific load-bearing requirements?

Chain pulleys can be customized to meet specific load-bearing requirements in various lifting applications. Here's how chain pulleys are customized:

1. Load Capacity:

Chain pulleys are available in different load capacities to accommodate a wide range of lifting requirements. Manufacturers provide specifications for the maximum load capacity that a chain pulley can safely handle. By selecting chain pulleys with appropriate load capacities, operators can ensure that the pulleys are capable of lifting the intended loads without exceeding their limits.

2. Chain Length:

The length of the chain used in a chain pulley system can be customized based on the lifting height or distance required. Longer chains allow for higher lifting heights, while shorter chains are suitable for applications with lower lifting requirements. Customizing the chain length ensures that the chain pulley system can effectively reach the desired lifting range.

3. Chain Material and Strength:

The material and strength of the chain can be customized to match the load-bearing requirements. Chains are typically made from materials such as alloy steel or stainless steel, which provide excellent strength and durability. The choice of chain material depends on factors such as the load weight, environmental conditions, and any specific requirements for corrosion resistance or special properties.

4. Sheave Configuration:

The configuration of sheaves in a chain pulley system can be customized to optimize the mechanical advantage and load-bearing capacity. Different arrangements of sheaves, such as single sheave, double sheave, or triple sheave, can be selected based on the desired lifting efficiency and the weight of the loads being lifted. Customizing the sheave configuration ensures that the chain pulley system can provide the necessary mechanical advantage for the specific load-bearing requirements.

5. Safety Features:

Chain pulleys can be customized with additional safety features to enhance load-bearing capabilities. These features may include load limiters, which prevent overloading of the chain pulley system, and safety hooks with latches or swivels to securely attach the load. Customized safety features contribute to safe lifting operations and protect both the operator and the load.

6. Specialized Applications:

In certain industries or specific lifting applications, chain pulleys can be customized to meet specialized requirements. For example, in industries such as entertainment or theater, where precise positioning and smooth operation are critical, chain pulleys can be customized with features like fine adjustment controls or quiet operation mechanisms. Customizations can also include specialized attachments or accessories tailored to unique load-bearing needs.

By offering customization options such as load capacity, chain length, material, sheave configuration, safety features, and specialized applications, chain pulleys can be tailored to meet specific load-bearing requirements. This ensures that the chain pulleys are optimized for efficient and safe lifting operations in various industries and lifting applications.

In which industries and settings are chain pulleys commonly employed?

Chain pulleys, also known as chain blocks or chain hoists, find widespread use in various industries and settings due to their versatility and lifting capabilities. Here are some industries and settings where chain pulleys are commonly employed:

1. Construction Industry:

Chain pulleys are extensively used in the construction industry for lifting and hoisting heavy materials and equipment. They are commonly employed in construction sites for tasks such as lifting steel beams, concrete blocks, scaffolding, and precast components.

2. Manufacturing and Industrial Facilities:

Manufacturing and industrial facilities utilize chain pulleys for a wide range of lifting applications. They are used for lifting and moving heavy machinery, equipment, and components during installation, maintenance, and production processes. Chain pulleys are particularly valuable in manufacturing industries such as automotive, aerospace, and heavy machinery.

3. Warehouses and Distribution Centers:

In warehouses and distribution centers, chain pulleys are used for efficient handling and storage of heavy goods. They are employed for lifting and moving pallets, crates, and containers, making the loading and unloading of trucks and shelves more manageable.

4. Shipbuilding and Maritime Industry:

Chain pulleys play a crucial role in the shipbuilding and maritime industry. They are used for lifting heavy ship components, such as engines, anchors, and propellers, during construction, repair, and maintenance operations. Chain pulleys are also employed in ports and harbors for cargo handling and ship loading/unloading.

5. Mining and Extraction:

In the mining and extraction industry, chain pulleys are utilized for lifting and moving heavy materials and machinery. They are commonly employed in mines and quarries for tasks such as lifting rocks, ores, and mining equipment.

6. Power Plants and Utilities:

Chain pulleys are employed in power plants and utility settings for various lifting applications. They are used for lifting heavy transformers, generators, and other equipment during installation, maintenance, and repair operations.

7. Entertainment and Event Industry:

In the entertainment and event industry, chain pulleys are employed for rigging and lifting purposes. They are used for suspending lighting and sound equipment, stage props, and scenery during concerts, theater productions, and other events.

8. Workshops and Garages:

Chain pulleys find application in workshops and garages for tasks such as engine lifting, vehicle maintenance, and repairs. They provide a reliable and efficient solution for lifting heavy automotive components.

9. Agriculture and Farming:

In the agricultural and farming sector, chain pulleys are used for lifting and moving heavy loads, such as bales of hay, animal feed, and farm equipment.

These are just a few examples of the industries and settings where chain pulleys are commonly employed. Their versatility, strength, and ease of use make them valuable lifting tools in various sectors.

editor by CX

2024-05-17